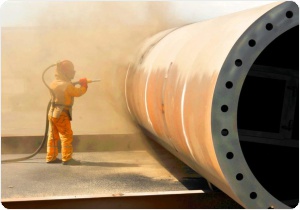

Abrasive blasting

At RSPC, with our technical expertise, skilled manpower and latest technologies, we can provide a wide range of abrasive blasting services. Due to the wear and tear of the weather as well as the contaminants, rust and stain settles on the surface and the only way to clean it is in the form of abrasive blasting. This method removes the dirt, debris as well as all the pollutants from the surface with the help of compressed air leaving it clean for paint, the coat or any further use.

It is a widely used cleaning method for the various surfaces of Brick, steel, stone concrete and many more We specialize in abrasive blasting a wide range of commercial and industrial items ranging from structural steel, I-beams, trusses, equipment, fabricated steel structures, pressure vessels, cooling towers, bulk storage tanks, silos, bridges, plus numerous other.

The different types of abrasive media than can be used during the blasting process includes glass beads, ground glass, aluminium oxide, black beauty slag, steel grit, steel shot, corn cob and walnut shells — each possessing unique benefits and features.

Our post-blasting coating systems range from alkyds, zinc-rich, epoxy, urethanes, polyurethanes, polyureas and metalizing. Our onsite mobile services allow us to blast and coat existing buildings, roofs, bulk storage tanks, silos, metal ceilings, metal siding, secondary containment areas, and most other items that can be sand blasted and coated.